Download TIA PORTALV15SP1 – Win 10,8,7 Real 100% Download TIA Portal V17 Full Version (GoogleDrive) Download Step7V5.6-Win10 Support S7-300,S7-400 PLC. Link download free and Fast at:my channel at: https://www.youtube.com/channel/UCVmd1gdNJzti0Ld8JHepHuw. With the latest TIA Portal V15 version (Totally Integrated Automation Portal), Siemens is extending its engineering system to include a number of new, realistic digitalization technologies to shorten engineering times. The key characteristics of the developments are an extension of the technical possibilities, an expansion of the portfolio of digitization, standardization and higher.

Tia Portal V15 Crack. Download Siemens Simatic TIA Portal v15.0 x64 full license Link download Siemens Simatic TIA Portal v15.0 full crack 100% working. Working with Siemens Simatic TIA Portal v15.0 full crack. Description: Choose the install you want Without taking into account and a long test of loyalty, it’s impossible to. TIA portal V15.1 SP1 Crack – Tutorial Using. Mod work Siemens TIA portal V13 V14 V15.1 SP1 Crack.

Download & Crack link on the end of the page

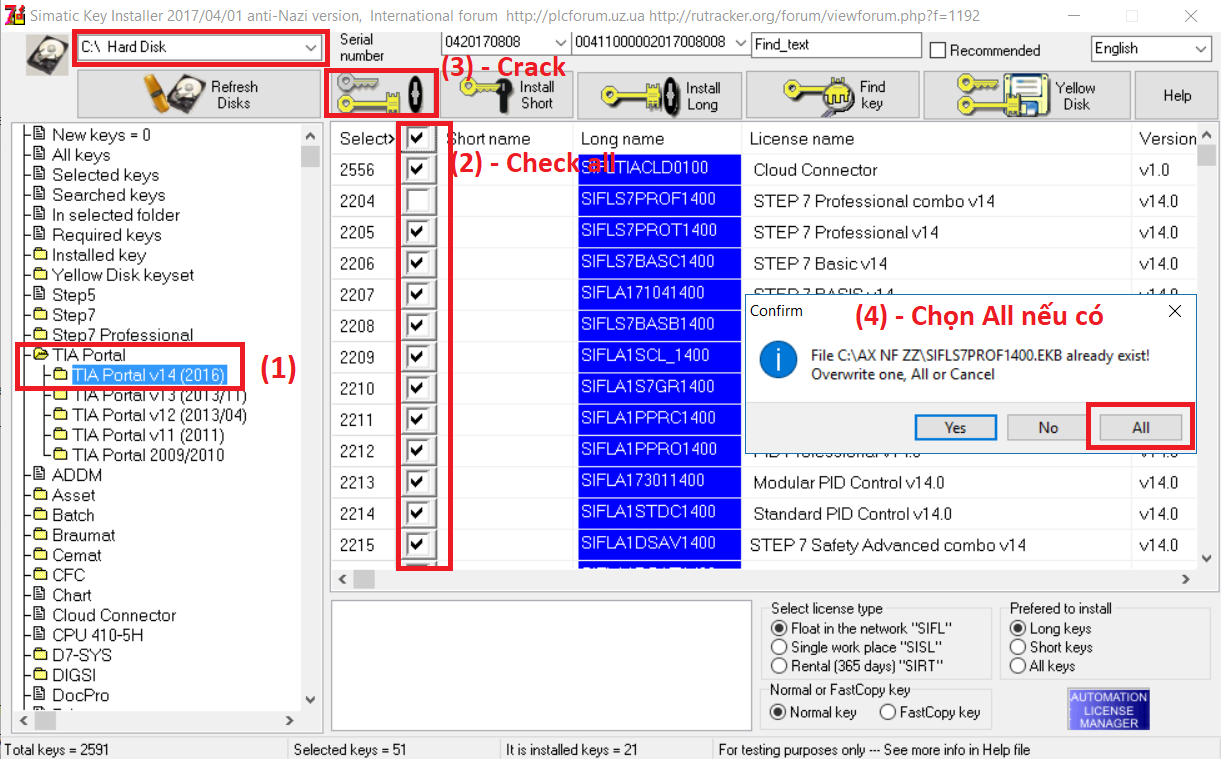

This video shows how to use EKB installer in order to activate correctly TIA Portal v15 Liciense

If you have any error during installation or after Watch:

How to Fix Automation License Manager Service

Totally integrated automation

Totally integrated automation (TIA) is a strategy (philosophies/architecture) in the automation technology, which was developed since 1996 by Siemens Automation and Drives. This strategy defines the interaction of extensive single components, tool (SW) and the services (spare part service, etc.) to achieve an Automation solution. The interaction performs integration across the four automation levels of the automation pyramid:

- Management level

- Operator’s level

- Controller’s level

- Field level

The consistency of TIA offers a simplification and cost savings to companies involved in the value chain (OEM, System integration planner and end customer).

Sub definition: automation is composed of the essentials of the drives (frequency converter + motor), a programmable logic control as well as a Panel to the visualization.

TIA Portal V13 Activation - EKB Install

ScreenShots:

Software Description:

Siemens SIMATIC STEP 7 Professional software isthe professional tool for the SIMATIC S7, SIMATIC C7 and SIMATICWinAC automation systems. It enables the user to use theperformance capability of these systems easily andconveniently.

Tia Portal V15 Crack Chomikuj

SIMATIC STEP 7 contains convenient functions for all phases of anautomation project:

– Configuring and parameterizing the hardware

– Specifying the communication

– Programming

– Test, start-up and service

– Documentation, archiving

– Operating/diagnostics functions

SIMATIC STEP 7 program tools:

1. SIMATIC-Manager:

The SIMATIC Manager manages all data belonging to an automationproject, regardless of the target system (SIMATIC S7, SIMATIC C7 orSIMATIC WinAC) on which they are implemented.

It provides a common entry point for all SIMATIC S7, C7 or WinACtools. The SIMATIC software tools that are necessary for processingthe selected data are automatically started by SIMATIC Manager.

2. Symbol-Editor:

With the tool Symbol Editor all global variables (in contrast tothe local formal parameters that are declared when the blocks areprogrammed) are managed. The following functions are available:

– Definition of symbolic designations and comments for the processsignals (inputs/outputs), flags and blocks

– Sorting functions

– Data exchange with other Windows programs

The symbol charts that are generated when this tool is used areavailable to all software products. Changes to a symbol parameterare therefore automatically recognized by all tools.

3. Hardware configuration:

The tool Hardware Configuration is used for configuring andparameterizing the hardware used for an automation project. Thefollowing functions are available:

– Configuration of the automation system Racks are selectedfrom an electronic catalog and the selected modules are assigned tothe required slots in the racks.

– The configuration of the distributed I/Os is done in the same wayas the configuration of the non-distributed I/Os; channel-granularI/O modules are also supported.

– CPU parameter assignment:

Properties such as restart characteristics and cycle-timemonitoring can be set menu-driven. multicomputing is supported. Theentered data are filed in system data blocks in the CPU.

– Module parameter assignment:

The user can specify all the adjustable parameters of the modulesin input screen forms. Adjustments via DIP switches becomeunnecessary. Parameterization of hardware modules occursautomatically during the CPU’s acceleration. Thus, a change of amodule can be made without another parameterization.

– Function module (FM) and communications processor (CP) parameterassignment:

This parameterization also occurs within the hardware configurationin the same way as the parameterization of the other modules. Forthis parameterization hardware-module-specific screen forms andrules are provided for each FM and CP (is included in the FM/CPfunctions package). The system prevents faulty inputs by offeringonly allowed entry options on the parameter assignment screenforms.

4. Communication configuration:

– Configuring and display of communication links

– Time-driven cyclic data transmission via MPI:

– Selection of communication partners

– Entering of data source and data destinationin a table.Generation of all system data blocks (SDBs) to be loadedand their complete transmission to all CPUs take placeautomatically

– Parameterization of the selected communicationblocks in the customary programming language (e.g., LAD).

Event-driven data transmission

– Definition of the communication links.

– Selection of the communication function blocks (CFBs) from theintegrated block library.

– Parameterization of the selected communication blocks in thecustomary programming

language (e.g., LAD).

5. System diagnostics:

System diagnostics offer the user an overview of the status of theautomation system. The display can be in two different forms:

– Display of text messages, which can be output directly andquickly.

– Pixel-graphics display within the Hardware Config display,offering the following options:

– Display of general module information (e.g., order number,version, designation) and module status (e.g., faulty)

– Display of module faults (e.g., channel faults) of thecentral I/O and DP slaves

– Display of alarms from the diagnostics buffer

For CPUs, additional information is displayed:

– Causes of malfunction during user program execution.

– Display of cycle duration (longest, shortest and last cycle).

– Display of the reserved and free memory.

– Capabilities and usage of MPI communication.

– Display of the performance data (number of possibleinputs/outputs, flags, counters, timers and blocks)

Tia Portal V15 Crack Indir

Installer Size: 106591 MB